Clean Electricity Via Your Plastics And Rubbish.

This article discusses Licella’s CAT-HTR Technology and Sierra Energy’s FastOx Gasification as follows:

· Licella’s Cat-HTR Technology: This innovative technology uses pressure and water at near or supercritical temperatures to chemically convert plastic back into oil. The process involves heating and pressurizing a mixture of end-of-life plastics, resulting in the production of HTL oil, also known as plasticrude. This oil can be used to create new plastics or biodiesel, providing an alternative feedstock for plastic manufacturing and generating electricity.

o Environmental Impact: CAT-HTR technology offers a sustainable solution by diverting non-recyclable plastics from landfills and incineration. It also has the potential to turn old landfills into valuable resources, creating a new mining boom for plastics.

· Sierra Energy’s FastOx Gasification: This process breaks down waste at the molecular level using heat, steam, and oxygen, producing synthetic gas (syngas), liquid stone, and liquid metal. Syngas can be used to generate electricity, while the other by-products have various industrial applications.

· Global Applications: Both technologies provide innovative solutions for waste management and energy production, with the potential to replace traditional landfills and reduce reliance on fossil fuels.

What’s great about both technologies is that they produce Syngas.

Syngas, or synthetic gas, is a mixture primarily composed of hydrogen (H₂) and carbon monoxide (CO), with smaller amounts of carbon dioxide (CO₂) and methane (CH₄). It is highly combustible and can be used as a fuel to generate electricity.

Electricity Generation Using Syngas.

1. Combustion in Gas Turbines:

Gas Turbines: Clean syngas is combusted in highly efficient gas turbines. The combustion process generates hot gases that expand and drive the turbine blades, producing mechanical energy. This mechanical energy is then converted into electrical energy by a generator.

Combined Cycle: The excess heat from the gas turbines and the gasification reaction is captured and converted into steam. This steam is then sent to a steam turbine to produce additional electricity, enhancing the overall efficiency of the process.

2. Combustion in Boilers:

Conventional Boilers: Syngas can also be burned in conventional boilers to produce steam. This steam is used to drive steam turbines, which generate electricity.

3. Combustion in Natural Gas Engine Driven Generators.

Syngas can be combusted in engines built to run on natural gas. These engines convert the chemical energy of the syngas into mechanical energy, which then drives an electric generator to produce electricity.

Wartsilla is a company that has purpose-built engines for natural gas would be an excellent choice for generating electricity using syngas.

Wartsilla 34SG Gas Engine.

A four-stroke, spark-ignited, lean-burn gas engine generating set.

Ideal for flexible baseload and balancing renewables applications.

Fast-starting capability for rapid response to renewable generation fluctuations.

High efficiency and reliability.

Capable of operating on natural gas, biogas, synthetic methane, and hydrogen blends.

Wartsilla 50SG Gas Engine.

Another four-stroke, spark-ignited gas engine generating set.

Suitable for flexible baseload and balancing applications.

High power density and fast-starting capability.

Low greenhouse gas emissions and minimal water consumption.

Can operate on natural gas, biogas, synthetic methane, and hydrogen blends.

These engines are designed to be highly efficient and reliable, making them perfect for converting syngas into electricity.

They also offer the flexibility to blend hydrogen, which aligns with future decarbonization goals.

4. Advantages of Using Syngas for Electricity Generation

Efficiency: Gasification and the use of syngas in combined cycle power plants can achieve higher efficiencies compared to traditional combustion methods.

Environmental Benefits: Syngas production from waste materials and biomass is considered a form of renewable energy. It helps reduce greenhouse gas emissions and diverts waste from landfills.

Versatility: Syngas can be used to produce not only electricity but also other valuable products such as transportation fuels, chemicals, and fertilizers.

By utilizing syngas, we can efficiently convert waste and biomass into valuable energy, contributing to a more sustainable and cleaner energy future.

Making Electricity From Plastic Recycling.

Australia-based Licella is the world leader in hydrothermal liquefaction. Their patented, next-generation Catalytic Hydrothermal Reactor (CAT-HTR) technology produces the most oil of any “plastic to oil technology” and is the only platform of its kind in existence.

Sure, I absolutely have a bias in favour of this company and the Australians who developed this technology, but it has taken a long time for them to get to this point, and I am so happy for them.

CAT-HTR uses pressure and water at near or supercritical temperatures to chemically change plastic back into the oil from which it originally came by severing its polymeric bonds. The hydrogen atoms are released, and the plastic is disassembled into its component parts.

As a result, a variety of substances are created, including waxes, oils, and plastics, which can later be transformed into other plastic goods or fuels. Cat-HTR, in contrast to other technologies, chemically recycles mixed plastics without the requirement of sorting out various plastic types.

The CAT-HTR process begins with the preparation of the feed, which is made up of a mixture of end-of-life and other formerly non-recyclable plastics. It is then heated to a very high temperature and pressurised, mixed with water, and more pressure is added.

It then spends about 20 minutes in the reactors before being de-pressurized. Approximately 15% of the output is gas, which is then used to power the process. The remaining 85% of the output is HTL oil, also known as plasticrude, which can then be used to:

1. As feedstock to make more plastics or

2. Made into Bio Diesel and used to power 100% carbon neutral power plants, 20MW Wartsilla 50DF multi-fuel power plants.

With the advent of Cat-HTR, a chemical recycling method that creates a direct replacement for fossil fuels:

1. The world’s plastic manufacturing industries now have another source of feedstock besides crude oil and natural gas.

2. Where ever you build a Cat-HTR plant you can be generating electricity and feeding the grid.

The thing about this technology that really excites me is that it could potentially turn mining plastics out of old landfills into a new mining boom all over the world. This is in addition to diverting plastic that cannot be economically “mechanically recycled” from landfill or incineration.

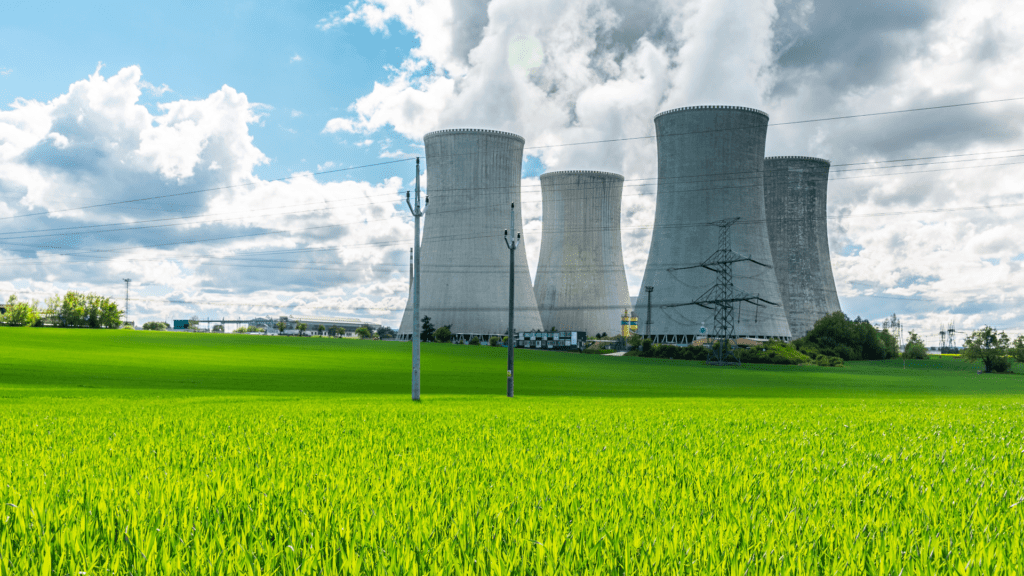

Eliminate landfills and generate electricity.

The American Sierra Energy company now offers the world a way to quickly process all waste in one action.

No need for sorting; just “chuck it all in,” and the FastOx Gasification process produces Synthetic Gas, Liquid Stone, and Liquid Metal. All of which can then be used to produce a variety of extremely valuable end products.

Synthetic Gas (Syngas), a fuel gas mixture primarily composed of hydrogen, carbon monoxide, and in some circumstances, carbon dioxide, is a product that can be used to generate electricity around the world.

‘FastOx Gasification’ breaks down waste at the molecular level using heat, steam, and oxygen.

1. Organic materials & waste are converted into syngas that is high in energy with no by-products. Syngas is created by combining hydrogen and carbon monoxide in various ratios.

2. Inorganics melt into liquefied metals and stone.

Syngas can be burned as fuel in gas turbines or gas-fired combustion engine power plants. Wartsilla offers a diverse range of engine power plants that can provide baseload power while running on either 100% synthetic or carbon-neutral methane, methanol, or hydrogen/natural gas blends.

I’m a big fan of their 20MW Wartsilla multi-fuel power plants, 38 of which can produce just under 600 MW and are located near Amman, Jordan, but due to gas shortages, they’re running on heavy fuel oil.

Without a shadow of a doubt, Fastox Gasification Plants should be used in place of landfills in every town on the planet.

[…] could be used on gas fueled engine driven generator units, another couple of ways we can make electricity from rubbish and get rid of the need to displace native flora and fauna to create landfill rubbish […]